How to Build a Plywood Drawer Box With Datos

I've made drawer boxes in a few unlike means throughout various projects. Admittedly, I've never taken the time to acquire how to create dovetail joints. I typically go for the pocket hole joinery method. The drawers I've made using this method take been in regular service for almost 4 years now, without the slightest indication that they're not operation 100%.

For a novice, drawer construction is probably the most fourth dimension consuming and idea provoking process of a given project. If not the construction itself, making sure the dimensions for the drawer opening, box, forepart and glides are all correct adds a level of difficulty that takes almost any simple project to the side by side level.

When I start thinking virtually how the drawers will fit into the project, I take one of two approaches:

- The drawer opening dimensions are more important than the dimensions of the drawer.

For example, if the but deciding cistron is that you demand to take the drawers centered and equally "padded" from all sides of the frame.

In this situation, frame out, or cutting out the drawer opening start. - The drawer box dimensions are more important than the opening dimensions.

For instance, if yous need to fit a certain size object in the drawer, the dimensions of the drawer box itself should be the deciding factor in the pattern.

In this situation, build the drawer get-go.

A seasoned woodworker may non take either approach, every bit they can hands conceptualize how everything will fit together. For the beginner, information technology's usually easier to have 1 piece of the puzzle in place commencement, before working on the side by side one.

A seasoned woodworker may non take either approach, every bit they can hands conceptualize how everything will fit together. For the beginner, information technology's usually easier to have 1 piece of the puzzle in place commencement, before working on the side by side one.

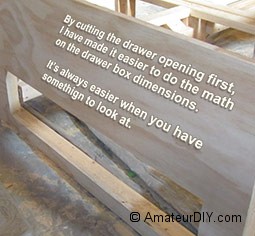

In my current projection, the platform bed, it is more important that the drawers fill the width of the opening provided by the bed frame. So, I cut the drawer openings first. Having this done, it's much easier to come up up with the dimensions of the drawer box itself.

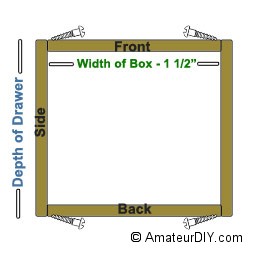

Now that nosotros have our opening, the dimensions of the box is simple arithmetic:

Drawer Box Width = Drawer Opening Width – (Drawer Slide Thickness * 2) – 1/xvi″

Drawer Box Height = Drawer Opening Tiptop – 1/two″

Now, let's explain. The elevation is pretty simple, nosotros want i/four″ clearance on the top and bottom of the drawer, so it doesn't rub against the frame. The width, however, depends on your drawer slides. You'll need to know ahead of time what glides y'all'll be using. I have used the Accuride 22″ Total Extension Self-Shut Slide in but about every one of my projects. Accuride is a trusted name, they're affordable, the full extension is well worth it and the self-endmost action "grabs" the drawer and pulls it close when yous go within almost an inch of the frame. Not to mention, 22″ volition fit a 24″ depth opening very nicely; 24″ is ane of the virtually mutual opening depths.

The Accuride slide is i/two″ thick, which is enough to give it that 100 lb. rating, while non being so thick that it significantly reduces your drawer width. I like to give the drawer slides a combined actress one/16″ to work with, every bit seen in the formula higher up. They seem to slide more than smoothly that mode.

Drawer Sides, Front & Dorsum

At present that the dimensions are out of the manner, let'south go to the construction. If you take a lot of boxes to brand, exist smart about how you cut your plywood (assuming you lot're non using solid wood). Drawer boxes use a lot of fabric (4 sides, a lesser and a confront), so it's important to get the nigh out of your 4×8 plywood sheets.

At present that the dimensions are out of the manner, let'south go to the construction. If you take a lot of boxes to brand, exist smart about how you cut your plywood (assuming you lot're non using solid wood). Drawer boxes use a lot of fabric (4 sides, a lesser and a confront), so it's important to get the nigh out of your 4×8 plywood sheets.

The drawer front and dorsum will width volition exist determined by the thickness of your wood, typically iii/iv″.

Front/Dorsum Width = Box Width – (Thickness of Forest * 2). Typically, Box Width – 1 i/2″

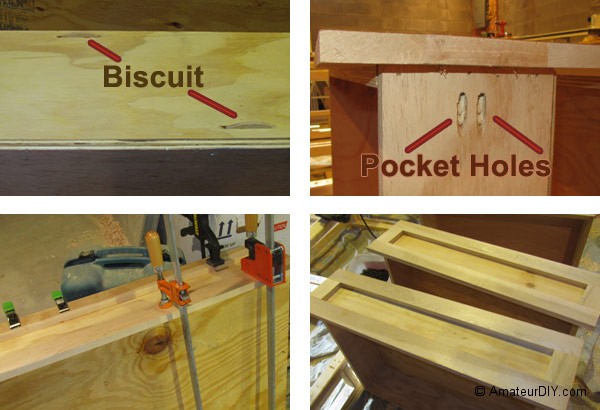

Cut your pieces then join them with pocket hole joinery. Screw into the rear of the dorsum panel, as it won't be visible. How you attach the forepart depends on your drawer confront. If you are using a frame and panel face, you'll want to screw into the outside face up of the front end panel, as information technology volition be covered by the drawer front finishing piece. However, if you lot're using a simple face frame method, as I am, you need to spiral into the inside of the front panel. They'll be visible on the inside of the drawer box, simply that's not a large bargain for most people.

Drawer Bottom

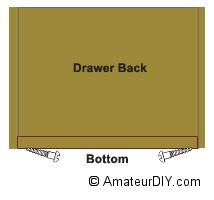

Wait! Before you screw the sides, front and back together, you lot demand to consider how yous'll exist joining the drawer bottom to the box. The method I like best is to rabbet a groove around the inside perimeter of the drawer box, which the drawer bottom can "slide" into. If using this method, yous demand to cut the groove with a router, and so slide the bottom into place earlier yous completely spiral the box together. This method is more intermediate, takes fourth dimension, and requires router skill. If this is your first project, I'd suggest taking the easier route and simply spiral the bottom to the box.

Wait! Before you screw the sides, front and back together, you lot demand to consider how yous'll exist joining the drawer bottom to the box. The method I like best is to rabbet a groove around the inside perimeter of the drawer box, which the drawer bottom can "slide" into. If using this method, yous demand to cut the groove with a router, and so slide the bottom into place earlier yous completely spiral the box together. This method is more intermediate, takes fourth dimension, and requires router skill. If this is your first project, I'd suggest taking the easier route and simply spiral the bottom to the box.

You can create pocket holes on the underside of the drawer lesser, then pocket hole screw information technology to the box. Or, if you cutting the bottom to the full width and depth of the drawer box and wood screw it directly to the bottom of the box (through the plies). Remember, if y'all have this approach, your drawer sides, front and bottom need to be three/four″ shorter than previously calculated.

Drawer Face

And finally, the finished confront of the drawer. Unless your guests have a bad habit of walking in and opening all of your drawers, this is the part that most people will see. There are and so many techniques to creating drawer fronts, I've used but a few. By far, the easiest method is to simply create a face frame and attach it to the drawer forepart console. The frame stiles and rail demand merely be thick plenty to encompass the visible plies on the plywood and the drawer opening. two″ stiles and rails is typically enough for this purpose.

I fix the face up frame parts, and so put them together with pocket hole joinery. Once that'south complete, I choose to attach the face frame with biscuits and pocket hole screws. If you don't take a beige joiner, you tin ever adhere it with woods screws drilled through the inside of the front panel and into the back of the face up frame, maybe coupled with pocket hole screws on the sides.

Source: https://www.amateurdiy.com/woodworking/building-drawer-box/

Komentar

Posting Komentar